Liner System for new and existing chimneys

The Pumice Flue Lining range also includes a range of 18 liners in diameters from 130mm to 1000mm

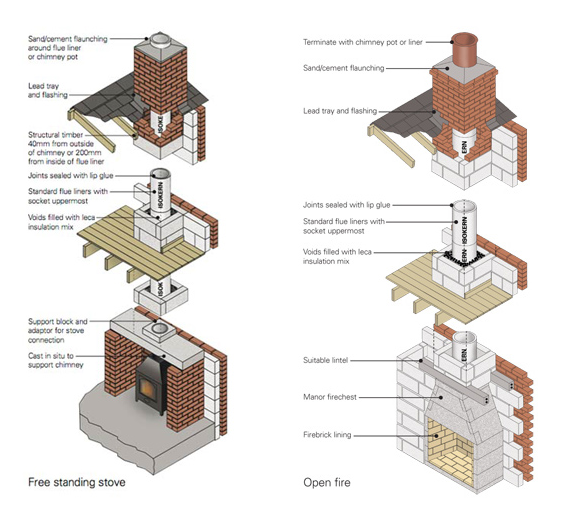

The insulated flue liner for traditional build

Suitable for use with inserts, stoves, pellet stoves (outlet temperature minimum 150 °C), cookers, open fires and Manor firechests

- Lightweight materials, easy to handle and cut

- Highly insulating pumice for better draw and minimum heat loss

- 600mm and 1000mm lengths mean fewer joints and fast to install

- 18 flue sizes available

- Good resistance to temperature variations gives the maximum performance for your appliance

- CE certified to EN1857 with the designation T450, N2, D, 3, G.

- Irish Board of Agrément approval

Liner System Technical Specification

Structural Timber Clearances

A minimum of 38mm clearance must be maintained between the structural timber and the outer surface of the brick/block chimney or 200mm from the outer surface of the Chimney flue liner. Floor boards, skirting boards, and other non-structural components may be in contact with the chimney.

Offsets

Offsets can be achieved by using our pre-formed bends in 15, 30 or 45 degree angles. Lip glue must be used on all joints. An additional steel collar should be used to wrap around any cut joints between bends.

Flashing and Trays

Stepped flashing and trays should be fitted as per normal building practice. Lead trays should be turned up on the outside of the chimney flue liners by approximately 50mm.

Heights above Roof

Chimneys should generally terminate at least 600mm above the ridge or 1000mm above the highest point of intersection with the roof. Masonry chimney stacks should not exceed 4.5 times their narrowest horizontal dimension above the roof.

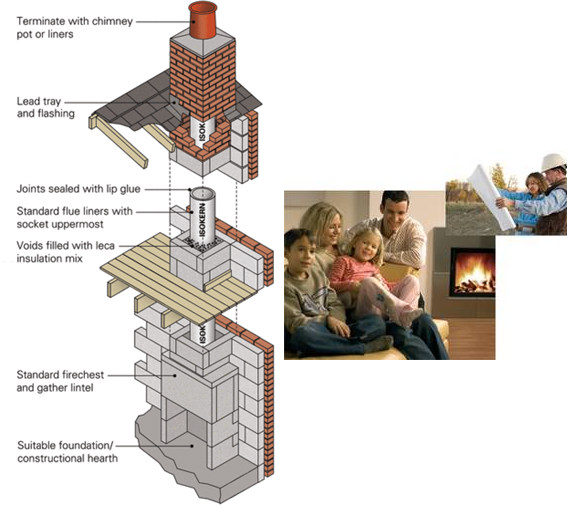

Relining

Isokern pumice liners are ideal for relining an existing masonry chimney.

The first liner has notches on its base to allow a rope to be secured under it. This enables the liners to be lowered down the chimney. Liners are joined together using steel collars

and lip glue. The rope controls the rate of descent until the first liner reaches its position on the gather or support block, then the knot will be loosened and the rope removed. A leca mix is poured down the chimney to surround the liners giving them support and insulation.

A separate instruction leaflet on relining is available.

ENABLES ENERGY EFFICIENCY